Power Generation (Gensets)

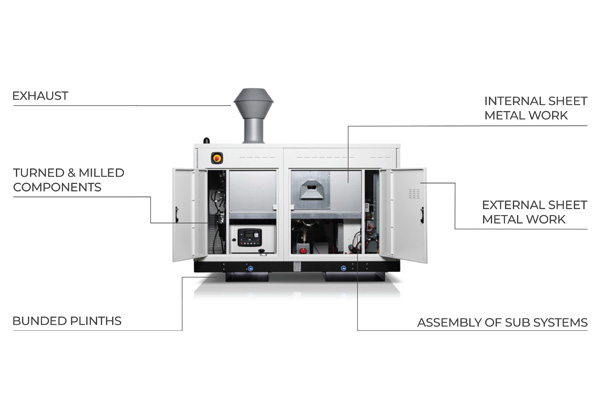

Sheet Metal Work and Assembly for Power Generation (Gensets)

Universal supports the power generation and remote power supply chain through in-house sheet metal fabrication, precision machining, and assembly. We manufacture everything from generator bases and chassis through to large acoustic enclosures, exhaust systems, and packaged sub-assemblies—built for demanding environments where uptime, durability, and safe access matter.

Recent work:

Our Power Generation Capabilities

Genset manufacture is rarely “just metalwork”. Most programmes bring practical packaging challenges: safe access for servicing, airflow and heat management, structural stiffness, vibration interfaces, lifting/handling points, corrosion protection, and repeatable assembly across builds.

Universal helps customers solve these challenges by combining design-for-manufacture input, in-house fabrication, precision machining, and sub-assembly—so projects move faster from prototype builds into repeat production, with fewer handovers and less rework risk.

How we support genset programmes

Depending on programme needs, we can also support:

What Our Genset Experience Covers

If you would like to discuss your genset project, our experts are ready to talk.