Welding & Complex Fabrication Specialists –

MIG, TIG, Robotic & Laser Welding

Production Welded Parts & Assemblies

Through our production welding service, we are able to TIG, MIG, CMT and Laser Weld parts. These can be produced in differing quantities so whether it’s a small batch run or higher production volumes we have it covered. We support the full range of requirements from simple welded parts, right through to welded assemblies with precision machined components.

Large Complex Fabrications

As we have a dedicated facility for the manufacture of large complex fabrications we are fully experienced in the fabricating of industrial metal assemblies. From large custom enclosures to full vehicle chassis, we have the skills, experience and facilities to make it happen. Here are just a few of our fabrication and assembly projects.

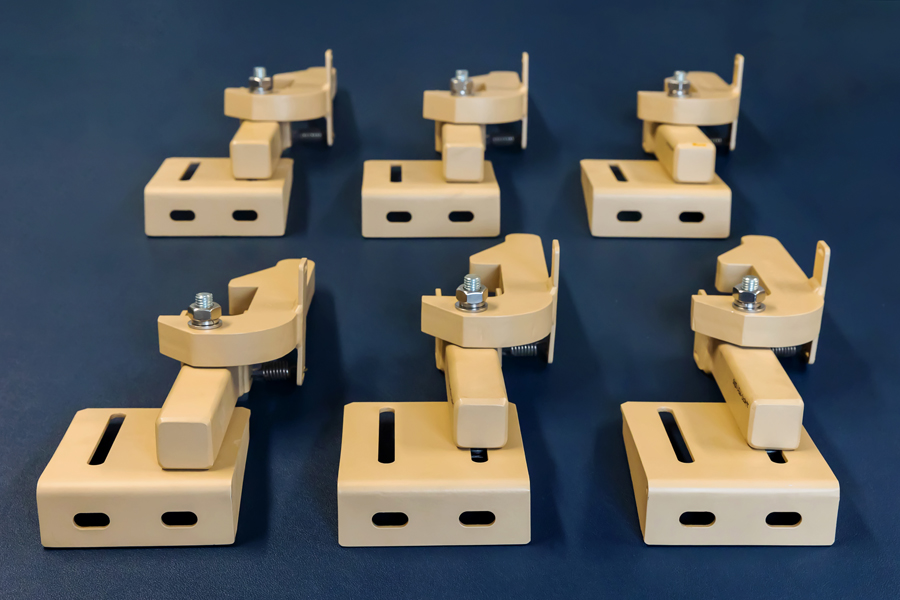

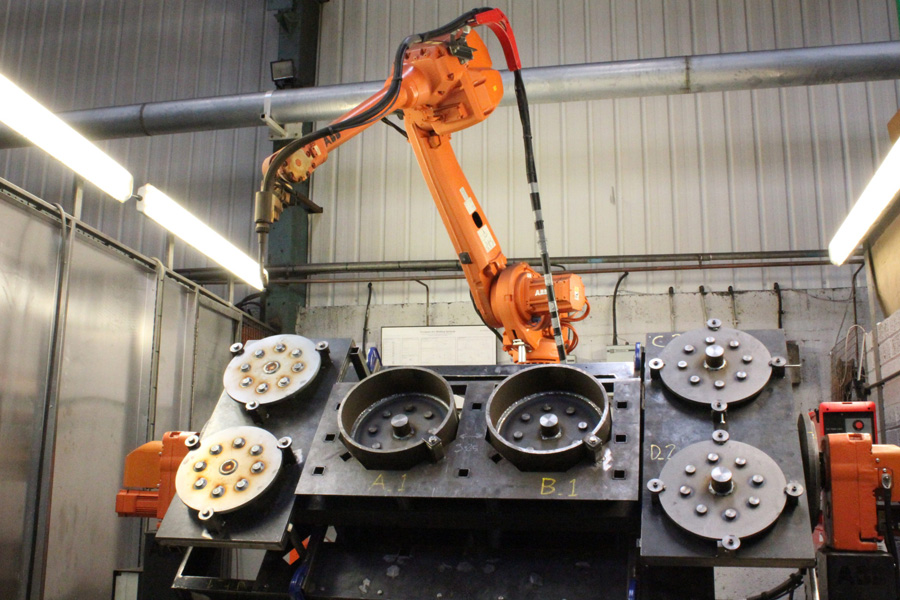

Robotic Welding

Robotic Welding automates the welding process for high volume or complex production applications, providing benefits like higher output rates, enhanced quality, reduced labour costs, more flexibility and great safety compared to manual welding. Our robotic welding cells are ideal for the automotive, aerospace, defence and construction industries and any industry requiring rapid, precise automated welding.

TIG Welding

TIG (Tungsten Inert Gas) welding, also called GTAW (Gas Tungsten Arc Welding) relies on an inert argon gas shield and non-consumable tungsten electrode to lay down meticulous welds on thin sections of delicate metals like stainless, aluminium and copper alloys. The process ensures very fine, neat weld seams demanded by aerospace, automotive, and precision tube fitting applications where cleanliness and eliminating warping are vital during welding passes done on reactive or thin-gauge base materials.

MIG Welding

MIG (Metal Inert Gas) Welding also known as Gas Metal Arc Welding (GMAW), feeds a continuous wire electrode protected by an inert gas to achieve high welding speeds. This efficient method joins steel and aluminium with quality and reliability across high-output industries like automotive and aerospace. The adaptable MIG process balances production volume, cost, and quality through its simplicity in operating and manipulating the arc. This facilitates the rapid fabrication of welded components demanded in assembly line manufacturing.

Laser Welding

Laser Welding (Laser Beam Welding) introduces the next level of precision to your project. This advanced welding process uses a focused beam of high-intensity laser light to fuse two or more materials together up to thickness of 5mm. Its key benefit is to produce clean, high quality welds with minimal distortion. Laser welding can be automated with robotic welding and its ability to achieve higher production rates and reduce material waste translates to cost savings and faster turnaround times on projects.

Our Welding Machines

FANUC ROBOTIC WELDING

Fanuc robotics welding cells x6

MANUAL MIG/TIG

Fronius CMT Welding Equipment

SPOT WELDING

Meritus Spot Welder:

ABB ROBOTIC WELDING

ABB robotic welding cells x3

LASER WELDING

Max Photonics MA1-65 Laser Welder

Welding Fabrication Case Studies

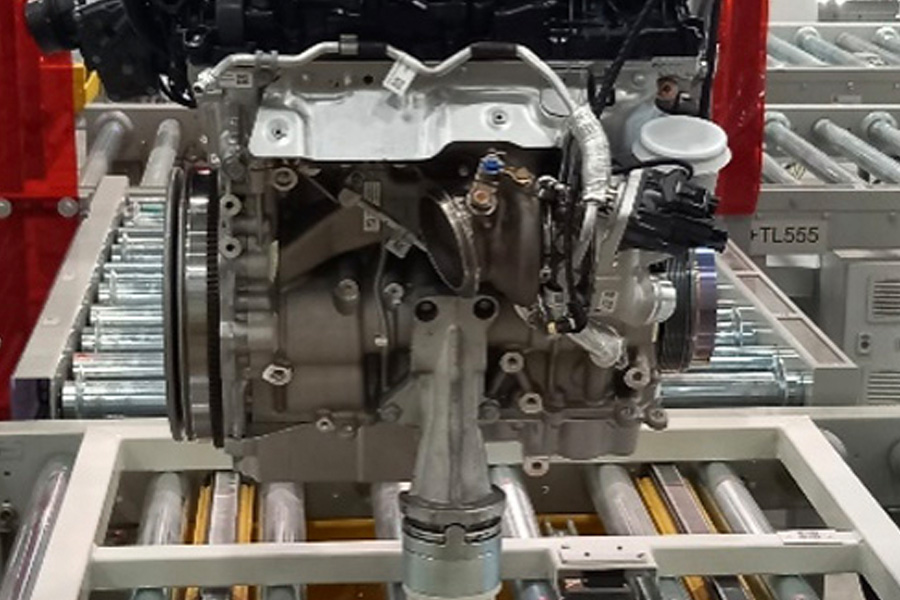

ROBOTIC WELDING CASE STUDY: ENGINE STILLAGE

Our welding fabrication solutions have made us a long-standing partner to premier automotive manufacturers like BMW. This project highlights why leading brands rely on us for transformative fabrication outcomes across storage, transport, and automation systems.

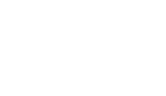

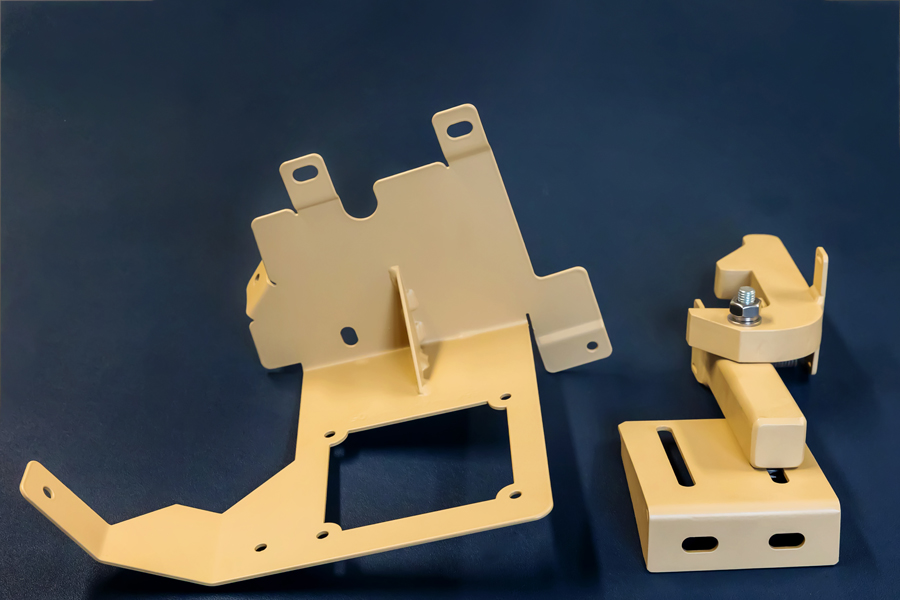

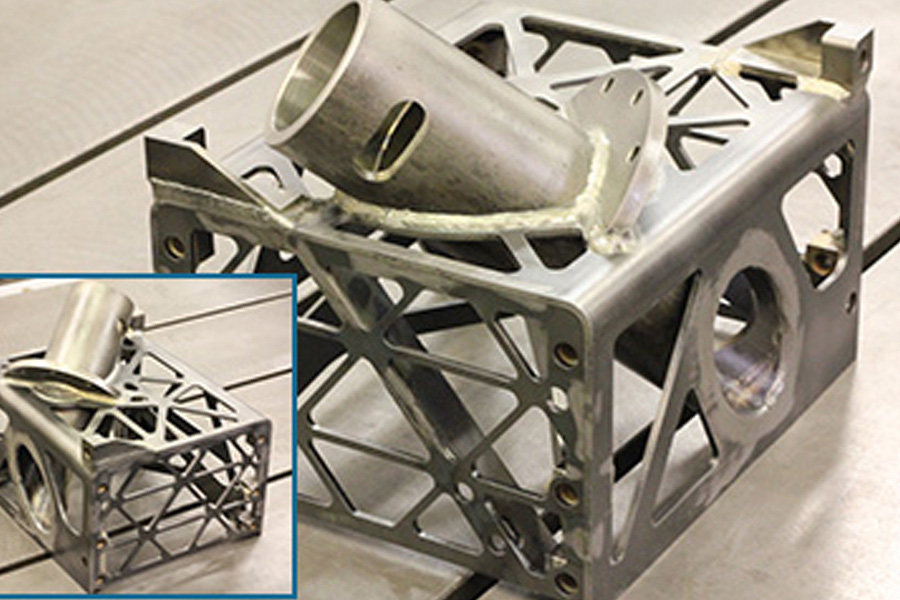

MIG/TIG CASE STUDY: DEFENCE SHAFT SUPPORTS

The housing design came about after many meetings with both the Universal team of design engineers and the customers. This moved the project away from using costly machined items, to a more cost effective laser cut fabrication which was quicker to produce.