Manufacturing Case Studies

An overview of case studies at Universal Fabrications

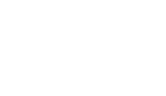

BMW Robot Welded Engine Frames Birmingham Car Plant

The BMW Hamms car plant in Hall Birmingham has expanded its storage facility to house over 6700 combustion engines including V8 and V12 engine types. Universal was awarded the contract to design, manufacture and install engine stillages (Platens) that worked with the automated conveyor systems and associated stores.

West Midlands Combined Authority Cycle Hire Docking Stations

West Midlands Combined Authority have launched their cycle hire scheme across the West Midlands. Working in conjunction with Serco and Pashley Cycles, Universal Fabrications manufactured the docking stations which can be found at major bus, metro and train stations, visitor attractions and city or town centres.

Universal Prototypes Fabricated Electric Vehicle Chassis for Ree Automotive’s Las Vegas Product Launch

Ree Automotive, an industry leading commercial vehicle provider contracted Universal Fabrications to manufacture a self-driving 3.5 Tonne electric vehicle chassis. The project was fully managed by a Project Manager supported by Lead Design and Welding Engineers.

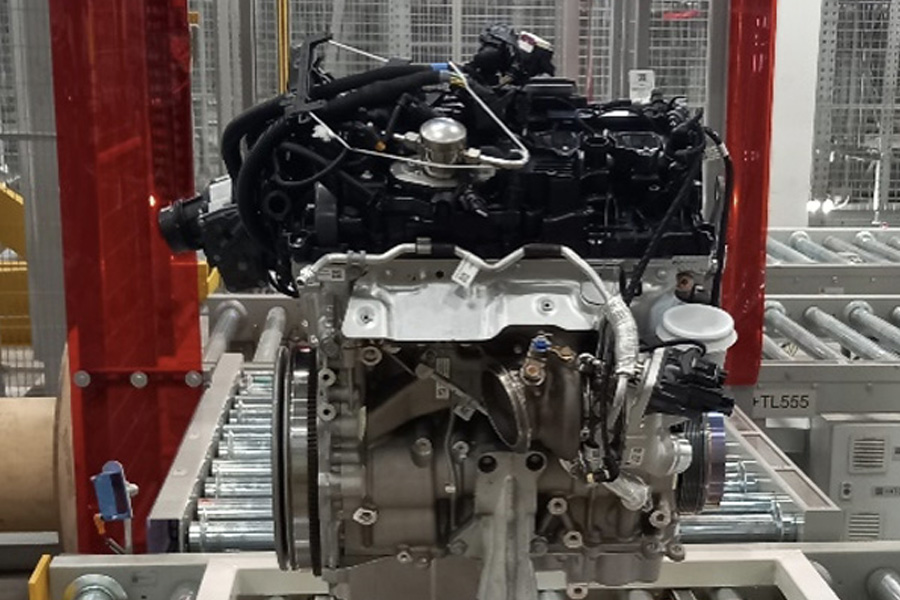

Complex Sheet Metal Fabrication | XC Off-Road Suspension System

Mastiff & Ridgback heavy armoured vehicles can now achieve impressive off-road performance following a major engineering upgrade delivered by NP Aerospace. Universal Fabrications supported NP Aerospace with the manufacture of the complex sheet metal fabrication for the suspension system.

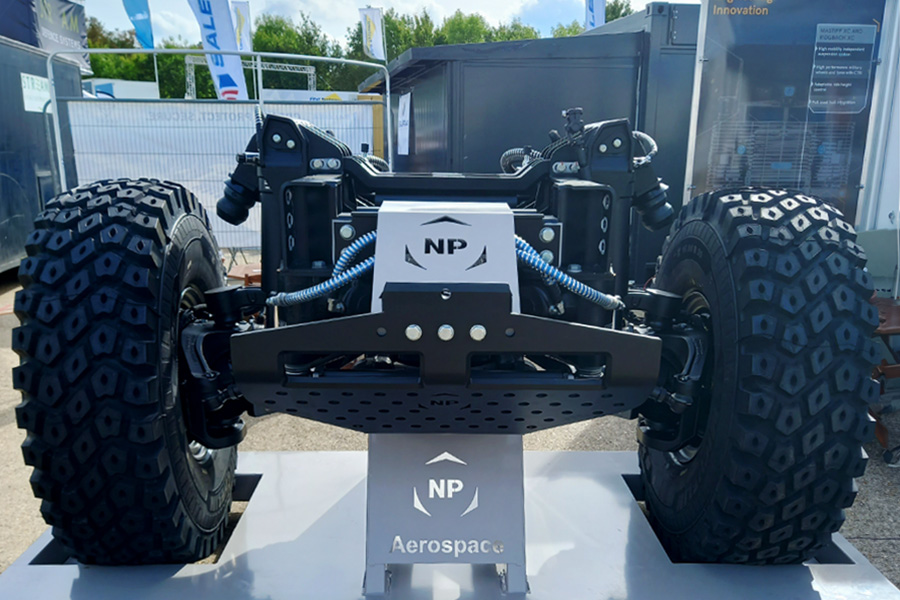

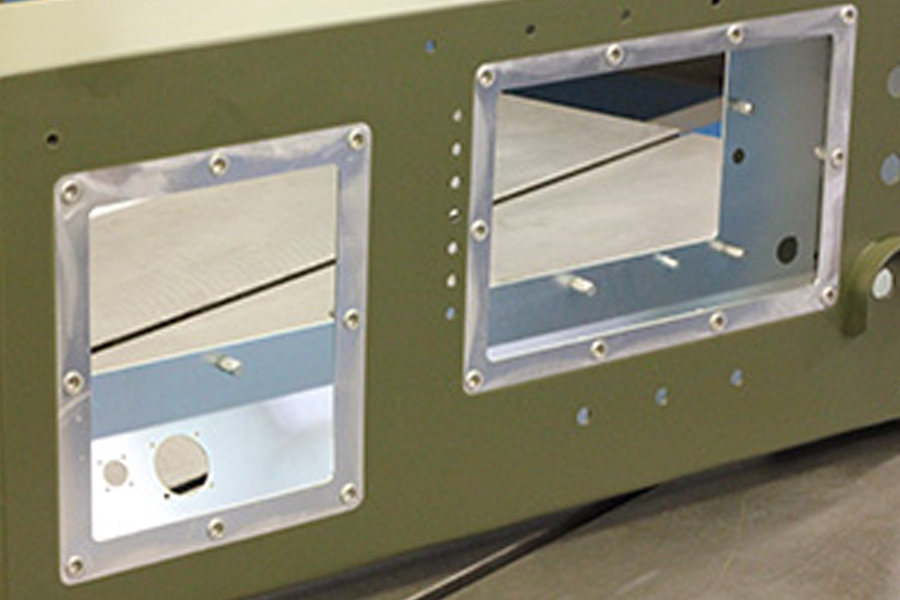

Battery Box

This battery box was designed by our customer and prepared for manufacture by our in-house design team. Whilst our client had concerns regarding overall size, weight capacity and weld strength, we focused our efforts to keep within the guidelines presented, and sign off was achieved quickly. Using our Amada punch/laser combi we were able to create a cost efficient solution to our client’s design.

Police Vehicle Security Cages

Brief: To design and manufacture a number of Police Vehicle Security Cages for single special vehicles and a full fleet of vehicles.

Design: Here at Universal Fabrications, we have designed and manufactured different variants of security cages for over 20 years. We were therefore able to draw on our expertise to complete the brief perfectly for our client.

Air Flow Diagnostic Housing

Brief: To produce a customer’s part from 3 drawn items.

Design: Universal Fabrications’ engineers responded with a re-designed ‘one-piece’ solution, therefore removing the weld assembly operations.

Outcome:

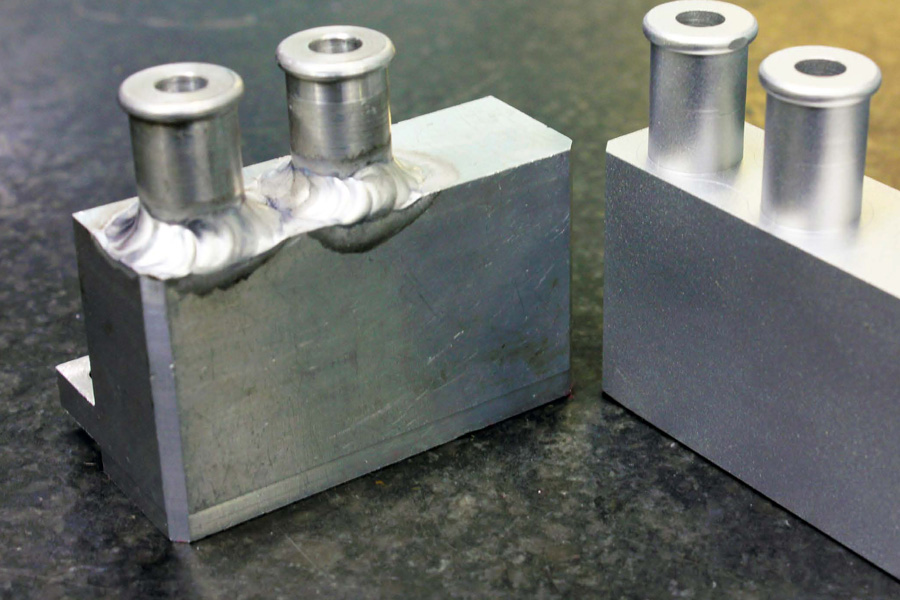

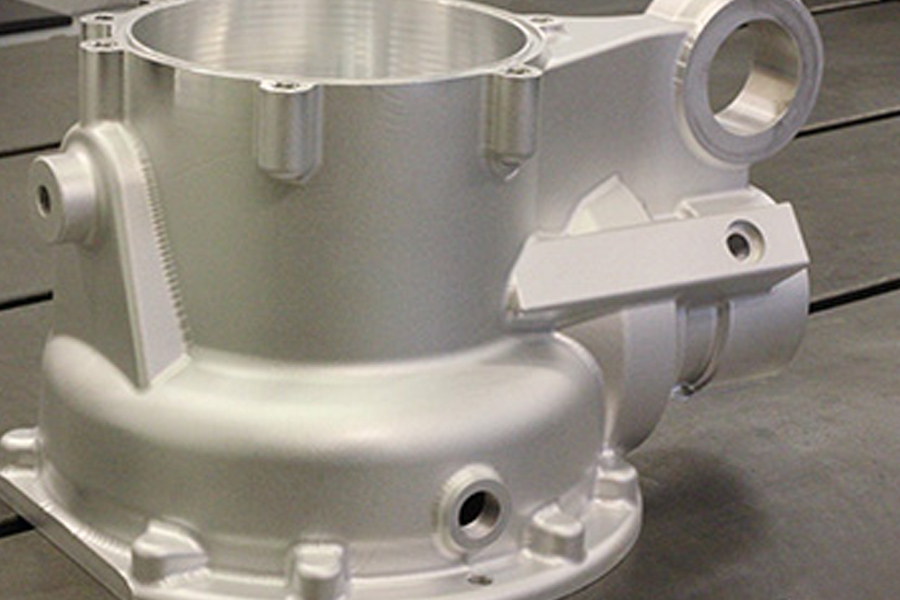

Special Vehicle Differential Casing

Brief: To machine from solid aluminium a 2 piece differential casing using a customer’s 3D model, with tight time constraints and very tight tolerances, this was a job for our most senior of staff members.

Solution: Using two of our 5 Axis machining centres, the parts were completed in time and finished to an excellent quality. The customer was delighted and we received fantastic feedback from their engineers doing the build.

Automotive Lifting Solutions

A gas strut was chosen to assist with lifting the load. This was then built into an easy-to-carry and use system made from sheet metal components and Tig welded together.

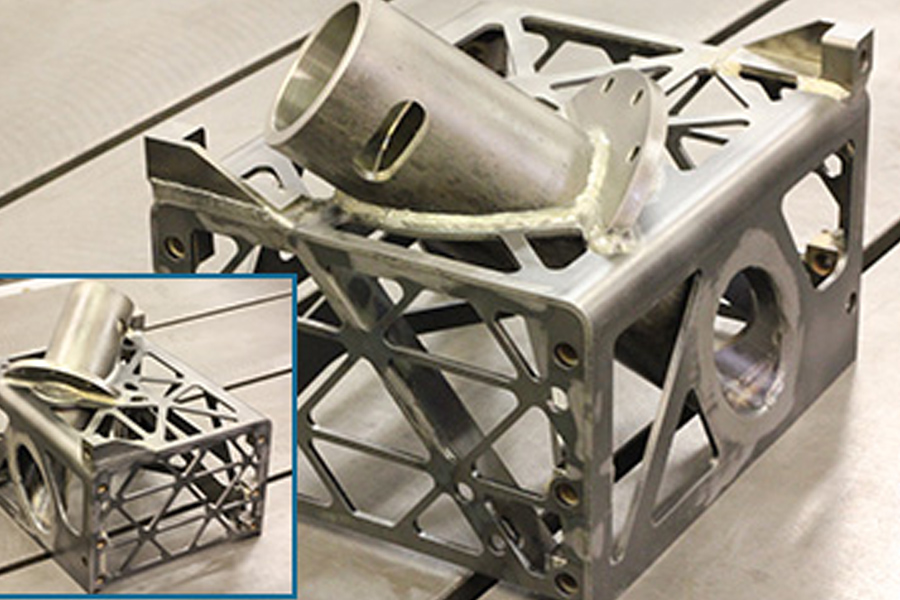

Defence Shaft Support

The housing design came about after many meetings with both the Universal team of design engineers and the customers. This moved the project away from using costly machined items, to a more cost effective laser cut fabrication which was quicker to produce.

Hot Swap Electronics Housing

The electronics housing was part of an order which consisted of over 100 parts and assemblies and included many different final finishes. With such a large amount of parts on order and the need for them to be delivered in sets, a great deal of production management was produced.

The result of the extensive planning was a smooth and unhindered build at the customer’s end which helped to complete their project ahead of time.

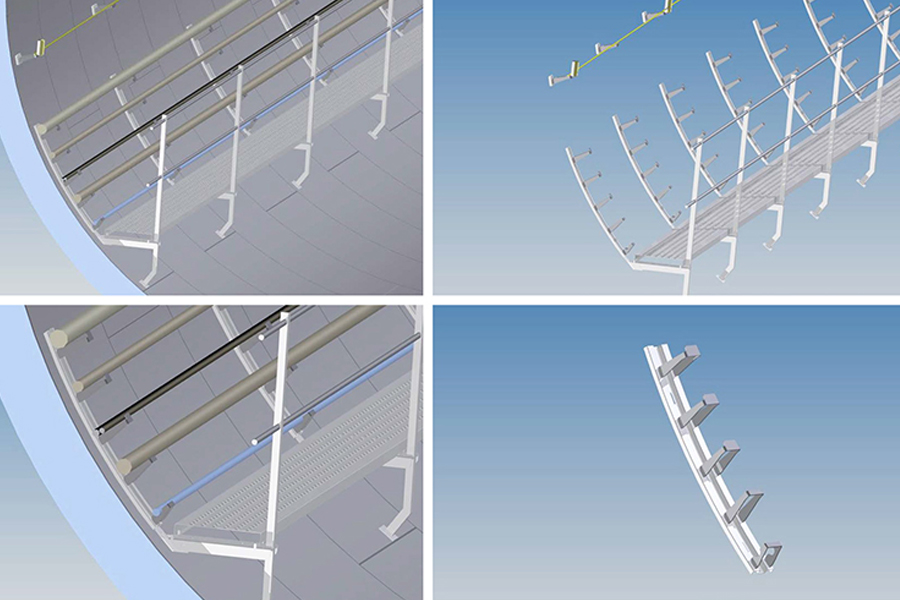

Channel Tunnel Rail Link

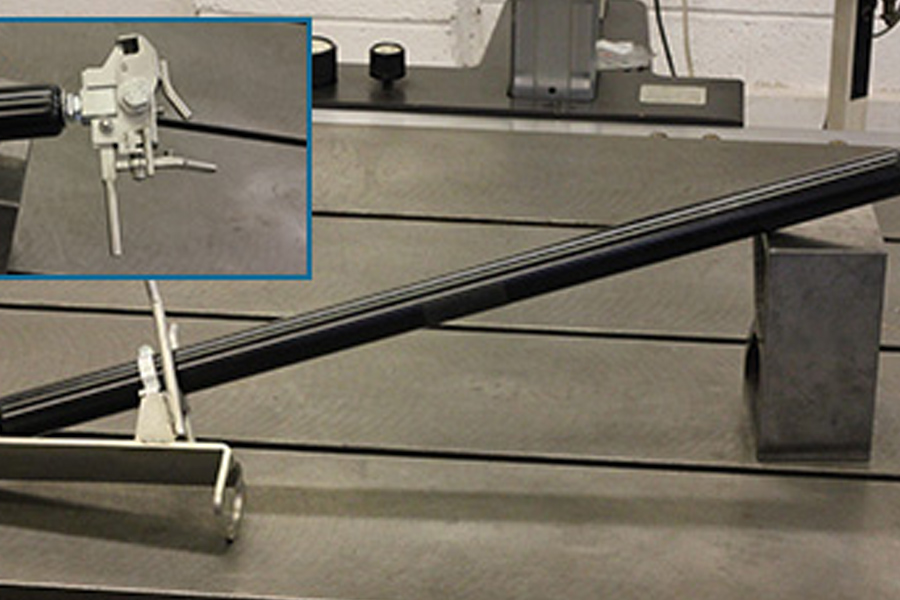

Brief: To engineer a design solution to hold the service pipes for the Channel Tunnel Rail Link TBM (Tunnel Boring Machine).

Design: An initial mock quarter pipe of the tunnel was manufactured and fitted with the newly designed brackets and steelwork. The content was presented in Paris and the contract was won.

Outcome: Universal Fabrications Ltd has much experience with the Tunnelling Industry and has completed significant contracts in the UK, Denmark, Singapore and Hong Kong.

Ready to talk about your project with our experts?