BMW Robot Welded Engine Frames Birmingham Car Plant

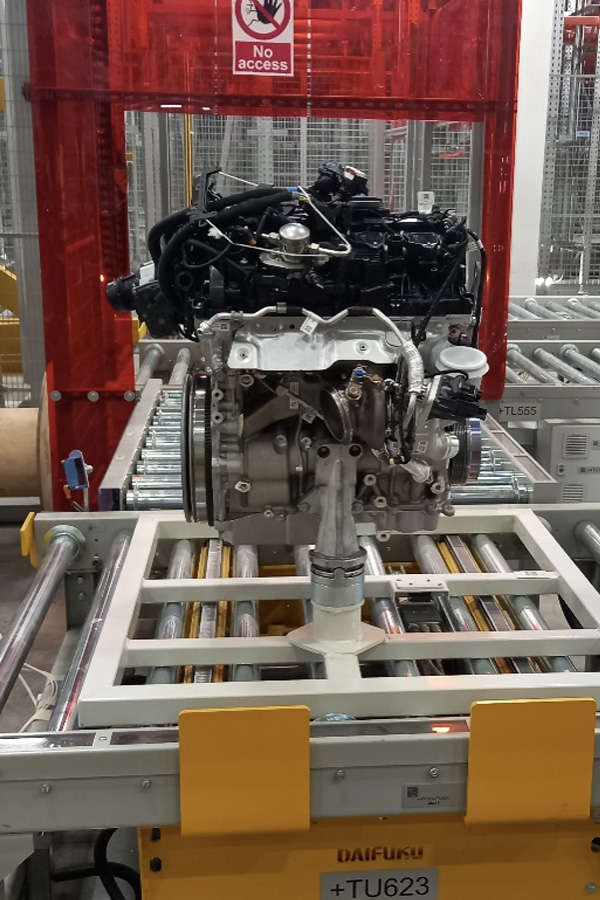

The BMW Hams car plant in Hall Birmingham has expanded its storage facility to house over 6700 combustion engines including V8 and V12 engine types. As part of this expansion, Universal was awarded the contract to design, manufacture and install engine stillages (Platens) that worked with the automated conveyor systems and associated stores.

Fabricated Engine Stillages – Prototype to Production

The stillage was designed to situate 3 engine types whilst maintaining balance during movement. The design was prototyped and tested to withstand the load, minimise frictional forces and travel safely and securely throughout the storage system. The production units were a robot welded box frame with a machined central spigot, finished off in a scratch resistant powder coated exterior. Using Universal’s Robotic Welding Cells and machining capabilities, 6700 units were produced over an 8-month production window.