Copper CNC Machining

Copper CNC Machining Services

From Prototype to Production

Based in the Midlands, we specialise in transforming your copper designs into precision-machined components, from one-off prototypes to production-ready assemblies. As leading copper machining specialists, we support businesses with high-accuracy parts, leveraging advanced CNC technologies while offering complementary fabrication services. Our in-house expertise and state-of-the-art facilities ensure a seamless, high-quality process for copper CNC machining in the UK.

We serve diverse industries, including electrical, plumbing, and automotive, capitalising on copper’s excellent conductivity, corrosion resistance, and malleability.

Contact us today on 02476 370 272, or submit your project details via the contact form below to discuss your copper machining needs in the Midlands.

A Trusted Partner for Copper Machining

Copper CNC Milling & Turning Specialists

We’re a reliable choice for copper projects where precision, conductivity, and quality are paramount. With extensive experience in precision machining copper using advanced CNC tools, complemented by welding and fabrication, we deliver consistent results for bespoke builds and large-scale production, meeting your expectations every time.

They’re not just machinists; they’re integral to our supply chain. Universal Fabrications’ expertise in CNC machining copper and supporting fabrication ensures our components meet the highest standards, even in demanding environments.

Precision Machining Copper for Multiple Industry Sectors

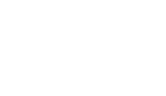

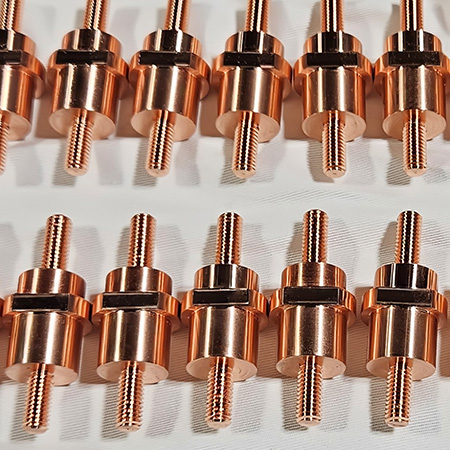

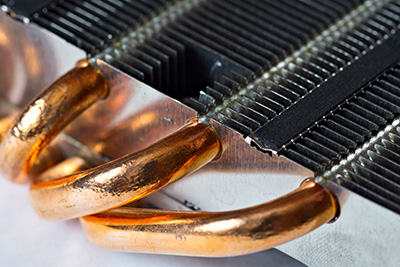

Universal supports its customers through the machining of copper-based components in addition to fabricating them into complex assemblies. Copper itself is a highly conductive metal with natural antimicrobial properties, excelling in precision machining for applications requiring electrical efficiency, thermal management, and durability. Our customers utilise our copper manufacturing experience for their electrical, plumbing, and automotive usages. This covers electrical connectors and busbars, plumbing fittings and valves, and such parts as heat exchangers used in the automotive sector.

Our customers benefit from copper-incorporated products with the following key characteristics:

Midlands-based Copper CNC Machining Specialists

Precision CNC Machining for Copper Components

As copper machining specialists, we focus on high-accuracy CNC operations to produce intricate components, from prototypes to full production runs. Our 3, 4, and 5-axis CNC mills (up to 2m x 2m envelope) and CNC lathes (500mm diameter) achieve tolerances as tight as ±0.01mm, handling copper’s softness with optimised tooling to prevent burrs. With crane handling up to 10 tonnes, we manage large-scale machined workpieces with precision.

We work with industry-standard copper grades, including:

We accept client-supplied materials or source from approved UK suppliers.

Supporting Fabrication and Welding for Machined Assemblies

To complement our core machining services, we offer tailored fabrication and welding. Processes like MIG, TIG, CMT, and robotic welding integrate seamlessly with machined parts, maintaining conductivity without compromise. All welders are qualified to BS EN ISO 9606-1, with BS EN 3834-2 accreditation for safety-critical assemblies.

Repeatable Precision with Robotic Assistance

For batch production of machined components, our robotic systems ensure consistent results, ideal for repeatable features like threads or grooves in copper parts. Overseen by certified engineers, this boosts efficiency for copper CNC machining specialist projects.

Copper Component Fabrication & Assembly Integration

We can fabricate and assemble machined components into complex assemblies. All of this is undertaken by an experienced, accredited welding and assembly team.

Testing & Surface Finishing for Copper Machined Parts

We conduct pressure and leak testing to verify machined enclosures. Surface finishing enhances performance:

Accredited Quality Systems

Our ISO 9001:2015 certification ensures traceability. We provide weld maps (if applicable), procedures, First Article Inspection Reports (FAIRs), and dimensional reports. Inspections use calibrated Coordinate Measuring Machines (CMMs) for machined precision.

From Prototypes to Production-Ready Copper Machining

Whether it’s a single machined prototype or a full production run, Universal Fabrications in Coventry is your partner for copper CNC machining in the UK, delivering quality, consistency, and control throughout.

FAQs: Copper CNC Machining and Fabrication

Get in touch to see how we can support your production requirements. Call us today on 02476 370 272 or send details of your project using the contact form below.